Golden Touch Painting and Drywall Inc is a local West Bloomfield Painting and Drywall Contractor with over 16 years experience, located in the West Bloomfield, Oakland County Michigan area. We provide our services to the Metro Detroit, Oakland County, Macomb County and Wayne County areas of Michigan.

We provide quality residential, industrial and commercial interior and exterior painting, drywall installation, drywall finishing, drywall repairs along with other remodeling and restoration services.

We provide quality residential, industrial and commercial interior and exterior painting, drywall installation, drywall finishing, drywall repairs along with other remodeling and restoration services.

We simply offer quality painting and drywall services at very competitive prices. We can meet your timetable and financial requirements without sacrificing quality.

We pride ourselves on attention to detail and custom quality work so you can rest assure that the ending results of anything we touch will be as good as gold! If you're looking for reliable and quality workmanship in the South East region of Michigan, you just found a painting and drywall company that provides you with great services in Oakland County and the West Bloomfield area! For a free estimate please call 248-787-0963

• Premium Grade Coatings Used

• Thorough Surface Preparation

• Fully Insured

• Quality Guaranteed

For a free estimate and other services, please contact us at:

(248) 787-0963

Painting can enhance the appearance of your home or workplace significantly, whether it is interior or exterior painting project you want to have done. We work with real estate agents and interior designers and all of them agree on one thing: PAINTING IS THE MOST COST EFFECTIVE UPGRADE OF YOUR HOME. There is nothing out there that will get you more return on your investment than simply painting your house. Professionally that is.

You can take a dull looking home with builder’s off whites, apply custom paint colors that will add character and bring new life to your house which will make it feel more inviting for you and your family. At the same time it will increase the value and equity of your home. www.oaklandpainter.com

That’s why many home owners that find selling their house difficult will turn to a painter for help. And we can help! Not just with your home but with any painting project you may have. Our experience professional residential house painters will also determine the best possible application method for the specific project, including airless spray technology.

There is a common misconception that airless spray painting is inefficient and wastes paint. But there are a number of factors that dramatically change the outcome of such a method of application. Our team of experienced professional painters knows how to use the industrial airless spray technology to maximize use of every gallon of paint.

This includes using the right pressure for the paint being sprayed and choosing the correct tip size for the specific work being performed to minimize over spray, therefore, less wasted paint and we are using straight paint (un-thinned). That results in having to spray fewer coats than if painted by roller or brush. Especially with a brush (which you have to thin so it spreads more evenly and brush marks are minimal, although not completely vanished) and that contributes to using about the same amount or in some instances even less paint than conventional methods of application, contradicting the common misconception.

Sprayed surfaces such as trim and doors tend to have a more uniform appearance that resembles the smooth surface of a fridge as opposed to surfaces that look like an orange peel (caused by roller) or brush marks (caused by brush). In any case, our interior exterior painters will help you with all of your painting needs in a courteous and timely manner.

Our team of Golden Touch tradesman and West Bloomfield Painters focus on individual service and attention to detail that produces dramatic results in a personal, professional and cost-effective manner. We take great pride in our ability to provide professional service and efficient completion of all our project needs.

Are you in need of Reliable and Quality

West Bloomfield Painters or a West

Bloomfield Drywall Contractor?

West Bloomfield Painters or a West

Bloomfield Drywall Contractor?

Within the many years of experience that Golden Touch Painting and Drywall and our team of West Bloomfield Painters has had in the commercial, industrial and residential areas of interior and exterior painting, drywall hanging, drywall finishing, carpentry, and many other remodeling and restoration services in the West Bloomfield Michigan area, our team of precision quality West Bloomfield interior painters, exterior painters, drywall hangers, drywall finishers and carpenters can take care of almost any situation within these fields of operation, from a straight forward paint job, to a complete renovation!

We have been contracted to paint, remodel or restore nearly every type of structure, be it a restaurant, an historic property, an apartment complex, a Home Owners Association, a custom home, a place of business, an entire commercial office complex or an industrial site, we've done it all.

|

| West Bloomfield Custom Interior Painting |

Golden Touch Painting and Drywall Inc is a company who has worked hard to earn a reputation for our quality craftsmanship and we look forward to showing the residents of West Bloomfield Michigan that it is well deserved.

Let us provide you with a few professional West Bloomfield

painters, to help keep your home or place

of business’s value up to full potential!

Our team of West Bloomfield Painter’s and tradesman do our best to try to give you your privacy while we work and will be more than happy to thoroughly answer any questions you may have.

Our quotation process is simple, without convoluted processes and fees. Step by step, Golden touch Painting and Drywall experts of tradesman and West Bloomfield Painters will walk you through your home or place of business to understand the precise needs of each individual room for any interior remodeling questions and inspect every curve and nook on the outside for exterior work.

Golden Touch Painting and Drywall's thorough and experienced West Bloomfield Painter, drywall or carpentry staff will make sure your home or businesses painting project, remodeling project or restoration project is complete, on-budget and on-time!

Whether you're a perfectionist looking for the best quality custom work or a Realtor simply looking to quickly fix up a property, you can assure our West Bloomfield Painters or tradesman from Golden Touch Painting and Drywall Inc will provide the necessary services you need with golden results. We strive to be one of West Bloomfield leading interior and exterior painting, drywall, and carpentry companies in Michigan.

Are you looking for Professionalism? Are you looking for a few reliable West Bloomfield Painters? Well you found us!

Golden Touch Painting and Drywall's team of qualified professional Tradesman and West Bloomfield Painters undergo thorough training in advanced painting, drywall and carpentry techniques and safety operations. Our staff has a positive and helpful approach towards answering customers’ questions and addressing your needs.

Attention to detail and custom finishes are our priorities. The most important part of a top-quality paint job is not just the painting; it is the preparation before paint is applied. Remember that paint is only as good as the surface it goes on. Our team of qualified professional Tradesman and West Bloomfield Painters take meticulous care in surface preparation and selection of outstanding surfacing materials and finishes in which we use, so you can trust any West Bloomfield Painter from us who is working on your job.

Believe it or not but carpentry, drywall and painting all deal with one another, each depending on the other to look their best, so when you have the best experts in each one of the field's putting together top quality work, you can bet on a A1 top notch quality job being performed, and that's what our team of qualified professional Tradesman and West Bloomfield Painters from Golden Touch Painting & Drywall Inc delivers to all of our customers.

Golden Touch Painting and Drywall and our team of qualified professional Tradesman and West Bloomfield Painters recognizes the importance of providing our services at times that are convenient and necessary to you. Therefore, we provide West Bloomfield Painter crews on off-hours and weekends so our work will not interfere with your normal day-to-day operations and business.

For all of our tradesman and West Bloomfield Painter employees, we encourage the free exchange of ideas and provide opportunities for training, employment, career advancement, and economic security fairly and equally to all who would apply themselves, as well as to provide a safe working environment by establishing good safety practices in compliance with current federal, state and local laws.

Michigan's Golden Touch Painting and Drywall Inc. is a group of West Bloomfield Painters, drywall and carpentry craftsman devoted to expanding painting, drywall and carpentry knowledge, and to preserve and beautify West Bloomfield Michigan and the surrounding areas.

Please do not get our team of qualified professional Tradesman and West Bloomfield Painters mixed up with your regular ordinary handyman service or other painting contractors in the Michigan area, because all of the individuals that work for Golden Touch Painting and Drywall Inc are professional and reliable craftsman, each specializing in their own field of operations with many years of experience under their belts. For instance, we have certain West Bloomfield Painters who are more knowledgeable and experienced dealing with high end residential custom repaints, also we have other professional West Bloomfield Painters who are more experienced with commercial painting aspects, others who are more experienced with interior painting in West Bloomfield, and others who are more experienced with exterior painting in West Bloomfield and the same goes for our West Bloomfield drywall crews and West Bloomfield carpentry crews.

So whatever your needs might be, you can rest assure that our team of qualified professional Tradesman and West Bloomfield Painters from Golden Touch Painting and Drywall Inc of West Bloomfield, our West Bloomfield Painters in Michigan will provide you with the best qualified professionals, performing the best quality work and craftsmanship available each in their own fields of operation.

West Bloomfield Michigan Painting Specials:

- 15% off- complete repaints of Residential Exteriors to the first 20 customers to sign up this winter for the spring and summer 2012 season.

- 10% off- complete repaints of Residential interiors (Dec. – Apr.

- Multiple room discounts, Realtor discounts

- Referral bonuses

- Preferred customer discounts

- 15% off- complete repaints of Residential Exteriors to the first 20 customers to sign up this winter for the spring and summer 2012 season.

- 10% off- complete repaints of Residential interiors (Dec. – Apr.

- Multiple room discounts, Realtor discounts

- Referral bonuses

- Preferred customer discounts

Do you live in the following Mi. cities and in need

of a few West Bloomfield Painters?

of a few West Bloomfield Painters?

Our team of qualified professional Tradesman and West Bloomfield Painters are happy to provide our Interior and Exterior Painting, drywall and carpentry services to all of these communities and cities in the Oakland County Michigan area.

Addison

Auburn Hills Berkley Beverly Hills Bingham Farms Birmingham Bloomfield Bloomfield Hills Brandon Clarkston Clawson Commerce Farmington Farmington Hills Fenton Ferndale Franklin Village Groveland Hazel Park |

Highland

Holly Huntington Woods Independence Keego Harbor Lake Angelus Lake Orion Lathrup Village Leonard Lyon Township Madison Heights Milford Northville Novi Oak Park Oakland Orchard Lake Ortonville Oxford |

Pleasant Ridge

Pontiac Rochester Hills Rochester Rose Township Royal Oak South Lyon Southfield Springfield Sylvan Lake Troy Walled Lake Waterford West Bloomfield White Lake Wixom Wolverine Lake |

Oakland County Zip Codes:

48007 48009 48017 48025 48030 48033 48034 48037 48067 48069 48070 48071 48072 48073 48075 48076 48083 48084 48085 48086 48098 48099 48165 48178 48220 48237 48301 48302 48304 48306 48307 48308 48309 48320 48322 48323 48324 48325 48326 48327 48328 48329 48331 48332 48333 48334 48335 48336 48340 48341 48342 48346 48348 48350 48356 48357 48359 48360 48362 48363 48367 48370 48371 48374 48375 48376 48377 48380 48381 48382 48383 48386 48390 48393 48442 48462

· There’s Only So Many Hours in a Day: Where will you find the time to get the job done? This weekend? Next weekend? Next month? Doesn’t it always seem like something else (life!) seems to happen? Doesn’t always seem like most home projects end up taking longer then what you thought they would? There’s a wedding, there’s a ballgame, there’s a function at school, a deadline is looming at the office – you get the idea. You can tell yourself you will eventually get to it, but in the meantime, you could have contracted the paint job and had it completed.

· It’s a Long Way to the Ground: In other words, when you fall off the ladder, it’s going to hurt. Golden Touches West Bloomfield Painters are not only skilled in their profession, but they are experienced with the equipment needed to get the job done. If your spouse comes home to find that you just ruined her bed of roses because you dropped the paint bucket from the second story … you’ll wished you would have thought of calling that painting company she had suggested earlier.

· Keeps You Healthy: If your home is older than 1978, it may contain leaded paint. A professional West Bloomfield Painter will take steps to ensure that you and your family will not be at risk when it comes time to removing old paint. There are also fumes and chemicals to consider … fumes and chemicals that you’d be breathing if you were tackle the paint job yourself. How much will the emergency room visit cost you when you slip in the paint puddle you made on the floor? Stay healthy and let a professional assume the risk.

· No Clean-up: Possibly the worst job in conjunction with the actual painting. A professional West Bloomfield Painter will safely dispose of toxic items as well as any residue that may remain from the job, including those little “whoops” that were made along the way.

· They Don’t Buy the Cheap Stuff: A professional West Bloomfield Painter knows what works and what doesn’t. If you think that paintbrush you got at the dollar store will do a nice job for you, think again, good luck making a straight line with it. It will only cost you time and more money to re-do and re-cover the project. Someone who has the best quality of supplies, will do the best quality of work. How much money would it cost you to purchase professional grade painting supplies? Why not just hire the professional? It Just Makes Cents!

Metro Detroit Michigan's Golden Touch Painting and Drywall Contractor paints a pretty picture for Michigan Charities and Churches.

Mike DeLuca from Golden Touch Painting and Drywall Inc. (248) 787-0963 and Mark Maupin from Brick Repair LLC paint one heck of a pretty picture of what the Metro Detroit community is really about!

When I spoke with Mike DeLuca, he told me he was looking forward to giving back to the community that had kept them working through his own hard times. Mike is one of those truly honest contractors, who is delighted and feels blessed to have the opportunity to give back to the community. Mike and Mark have been working in Michigan’s past good years and also now during these unfortunate rough times of our economy.

Mike Said “It has been rough for the past few years. I know that a lot of Michigan contractors have been struggling to keep their heads above water, and I was no exception. Our economy is not the same as it was 7 years ago. I feel blessed to have a roof over my head and to be able to keep busy during these rough times of our economy. I was blessed to have a few local churches’ help me out when I needed it. So it only feels right to give back.”

Mike Run's a small painting & drywall company in West Bloomfield Mi. they have been in the home repair and restoration industry for over 15 years. They are happy to provide the following services.

Interior & Exterior Painting, Epoxy floor coatings, Murals, Staining and varnishing, Faux Finishes (multiple methods), Wall paper removal, Wall paper hanging, Caulking, Fire and Water Damage Repair, Insurance work, Power washing, Block or Concrete water proofing, Deck restoration, Aluminum fence painting, Steele structure coatings, Sand Blasting, Drywall Installation, Drywall Repair, Drywall Hanging, Drywall Finishing, Popcorn ceilings & other textured wall & ceiling applications, Rough & Finish Carpentry, Rotted wood replacement, Basement Finishing, Interior Demolition.

Mike and Mark are looking to find a church or charity to provide their services to free of charge. They said “We will provide the labor and tools, if they provide the material. We have an opening available in our calendar on Mar. 15th and if we can find someone to help during that time it would be a great way to ring in the New Year”.

Mike DeLuca from Golden Touch Painting and Drywall Inc. (248) 787-0963 and Mark Maupin from Brick Repair LLC paint one heck of a pretty picture of what the Metro Detroit community is really about!

When I spoke with Mike DeLuca, he told me he was looking forward to giving back to the community that had kept them working through his own hard times. Mike is one of those truly honest contractors, who is delighted and feels blessed to have the opportunity to give back to the community. Mike and Mark have been working in Michigan’s past good years and also now during these unfortunate rough times of our economy.

Mike Said “It has been rough for the past few years. I know that a lot of Michigan contractors have been struggling to keep their heads above water, and I was no exception. Our economy is not the same as it was 7 years ago. I feel blessed to have a roof over my head and to be able to keep busy during these rough times of our economy. I was blessed to have a few local churches’ help me out when I needed it. So it only feels right to give back.”

Mike Run's a small painting & drywall company in West Bloomfield Mi. they have been in the home repair and restoration industry for over 15 years. They are happy to provide the following services.

Interior & Exterior Painting, Epoxy floor coatings, Murals, Staining and varnishing, Faux Finishes (multiple methods), Wall paper removal, Wall paper hanging, Caulking, Fire and Water Damage Repair, Insurance work, Power washing, Block or Concrete water proofing, Deck restoration, Aluminum fence painting, Steele structure coatings, Sand Blasting, Drywall Installation, Drywall Repair, Drywall Hanging, Drywall Finishing, Popcorn ceilings & other textured wall & ceiling applications, Rough & Finish Carpentry, Rotted wood replacement, Basement Finishing, Interior Demolition.

Mike and Mark are looking to find a church or charity to provide their services to free of charge. They said “We will provide the labor and tools, if they provide the material. We have an opening available in our calendar on Mar. 15th and if we can find someone to help during that time it would be a great way to ring in the New Year”.

We hope any information gained is beneficial please feel free to call Mike for a consultation on any painting project. (248) 787-0963 or go to www.oaklandcountypainter.com

If you’re in need of a great Masonry Contractor then please visit

Are you thinking about renting or buying a home or maybe updating and remodeling a house or home? Here are some important facts and information that our team of West Bloomfield Painters thought would be important about the dangers of lead based paints from Wikipedia:

Lead-based paint in the United States

From Wikipedia, the free encyclopedia

|

Due in great part to studies carried out by Philip J. Landrigan, paint containing more than 0.06% (by weight of dried product) lead was banned for residential use in the United States in 1978 by the U.S. Consumer Product Safety Commission (16 Code of Federal Regulations CFR 1303). The U.S. Government defines "lead-based paint" as any "paint, surface coating that contains lead equal to or exceeding one milligram per square centimeter (1.0 mg/cm2) or 0.5% by weight."[1] Some states have adopted this or similar definitions of "lead-based paint." These definitions are used to enforce regulations that apply to certain activities conducted in housing constructed prior to 1978, such as abatement, or the permanent elimination of a "lead-based paint hazard."

The U.S. Government and many states have regulations regarding lead-based paint. Many of them apply to evaluating a property for lead-based paint. There are two different testing procedures that are similar but yield different information. Lead-based paint inspections will evaluate all painted surfaces in a complex to determine where lead-based paint, if any, is present. The procedures for lead inspections is outlined in the HUD Guidelines, Chapter 7, 1997 Revision. The other testing is a lead-based paint risk assessment. In this testing, only deteriorated painted surfaces are tested and dust wipe samples are collected. This information will help the risk assessor determine if there are any lead hazards. Many property owners decided to get a combination of both tests to determine where the lead-based paint is present and what hazards are present as well. Risk assessments are outlined in the HUD Guidelines, Chapter 5. In addition, if a child is poisoned in a property, the owner may be required to perform abatement (permanent elimination of the lead hazard).

In 1996, the Lead-Based Paint Disclosure Regulation was enacted. It requires owners of pre-1978 "target housing" to disclose to potential buyers or renters all known information about the presence of lead-based paint and/or lead-based paint hazards in the property. It requires that the potential buyer or tenant be given the lead information pamphlet, "Protect Your Family From Lead In Your Home," or other United States Environmental Protection Agency-approved pamphlet as well as a specific disclosure statement. The option of whether to test for the presence of lead-based paint is left to the owner, so long as a decision not to test is disclosed.

EPA signed a new regulation (Renovation, Repair and Painting (RRP))[2] regarding the renovation of child-occupied buildings built before 1978 on April 22, 2008. The rule (Federal Register: July 15, 2009 (Volume 74, Number 134)) became effective April 22, 2010. Under the rule, contractors performing renovation, repair and painting projects that disturb lead-based coatings (including lead paint, shellac or varnish) in child-occupied facilities built before 1978 must be certified and must follow specific work practices to prevent lead contamination. EPA’s RRP rule impacts many construction trades, including general contractors and special trade contractors, painters, plumbers, carpenters, window installers, wood floor refinishers and electricians. Activities performed by all of these trades can disturb lead-based paint and have the potential to create hazardous lead dust. For most individuals, eight hours of training is required. However, individuals who have successfully completed renovation courses developed by HUD or EPA, or an abatement worker or supervisor course accredited by EPA or an authorized State or Tribal program, can become certified renovators by taking a four hour EPA-accredited renovator refresher training.

The RRP rule is controversial, primarily due to the increased cost remodelers incur as a result of having to set up dust containment apparatuses,[3] including sealing off doorways and HVAC ducts with plastic. Various national trade associations have been very vocal in their opposition,[4] some going so far as to sue the EPA. Still, the EPA is deliberating expanding the rule to require contractors to pass a third-party dust wipe clearance exam[5] to in order to complete remodel work in pre-1978 buildings.

Although the rule was not fully implemented until April 2010, certain elements were required before, and others required attention well before April 2010.

Before April 2009 – Contractors that disturb paint in homes, residential buildings, schools and child care facilities built prior to 1978 had to provide lead hazard information prior to the start of the job to building owners, occupants, and to the families of children using the facilities by distributing EPA’s new Renovate Right brochure.[6] As of April 2009 – Trainers could begin to apply to EPA or an EPA-approved state for accreditation, and, once approved, contractors and construction trade workers could begin to take the training to become certified. Beginning October 2009 – Firms could apply for EPA or state certification. Beginning April 2010 – All businesses engaged in renovation, repair or painting activities in homes, residential buildings, schools and child care facilities built prior to 1978 must be certified, use certified workers, and follow specific lead-safe work practices to prevent lead contamination.[7]

[edit] State action against the lead paint industry

The state of Rhode Island filed a public nuisance lawsuit in 1999 State of Rhode Island v. Lead Industries Association to get the former manufacturers of lead paint to pay for the clean up of current lead hazards in Rhode Island. After a trial that ended in a hung jury in 2002, the state refiled the case. In February 2006, the jury decided in favor of the state and said that Sherwin-Williams, NL Industries and Millennium Holdings would have to pay for the clean-up of lead paint in the state. On July 1, 2008, the Rhode Island Supreme Court in a landmark decision overturned the verdict,[8] dismissing the case stating that "the State of Rhode Island 'cannot allege' facts sufficient to state a claim for common law public nuisance against lead pigment manufacturers."[9]In 2007, the Missouri Supreme Court[10] and the New Jersey Supreme Court[11] also rejected the use of the public nuisance theory in lead paint lawsuits, leaving Ohio and California as the only two remaining public nuisance cases.

The California Supreme Court has reviewed the contingency fee agreement between the municipalities and private counsel. A briefing schedule is currently being set.[12] But in recent rulings the Supreme Court held the contingent fee agreement is improper stating that “When a government attorney has a personal interest in the litigation, the neutrality so essential to the system is violated.”[13]

While the City of Columbus, Ohio voluntary dropped its lawsuit against the paint industry after the Rhode Island decision,[14] the State of Ohio's suit remains.

[edit] Real estate maintenance and renovation

Humans can be poisoned during unsafe renovations or repainting jobs on housing that has lead paint. Therefore, homeowners are encouraged to carefully stabilize any deteriorated (peeling, chipping, cracking, etc.) paint in a lead-safe manner. More than 250,000 children in the United States have dangerous levels of lead in their bodies.[15]Working in a lead-safe manner means avoiding dry sanding, dry scraping, removing paint by torching/burning, the use of heat guns over 1100°F, machine-sanding or grinding without HEPA filtered dust collection or HEPA-filtered vacuum. These methods are now prohibited by the United States Department of Housing and Urban Development (HUD) because they have been proved to create significant levels of lead dust during remodeling, renovation and painting. They must be avoided, especially in properties where children under age six reside. Adult workers using unsafe work practices or improper protective gear may also become lead-poisoned.

There are specialized paint strippers for use with lead paint such as LEAD-OUT Paint Stripper, Strip-Tox, Lead-X, and others. Some of these specialized strippers render lead non-hazardous decreasing the risks associated with lead paint removal.

HUD requires a dust test for "clearance" at the end of any remodeling or repainting job be performed by a third-party professional who is independent of the entity performing the work. Contact your state's lead-poisoning prevention program (call the local health department or environmental department) or look in your Yellow Pages director under "lead paint" or "environmental consultants" to locate a lead-based paint professional who can do a clearance examination for your job.

Lead evaluations of paint are usually performed by a field testing method known as X-Ray fluorescence (XRF) using equipment such as the Olympus Innov-X LBP4000, RMD LPA-1, or the Thermo Scientific's Niton. XRF is the preferred method because it is not destructive and a reading is usually obtained in about 4–8 seconds with a 95% accuracy at the 2-sigma level.

Instruments of this sort have an inconclusive range, and when a reading falls in this range (range is different for each instrument and model), a paint chip may be taken and sent for laboratory analysis. Testing for lead in dust, water, and air also require laboratory analysis. Commercially available lead test kits are often used to test for the presence of lead, but they are not reliable and not authorized by HUD to be used in determining if a property is lead-based-paint free.

The home's year of construction can be a clue as to the likelihood that lead is present in its paint. Generally, two thirds of homes older than 1940 contain at least some lead paint, homes built between 1940 and 1960 have a 50% chance of containing such paint, homes built between 1960 and 1978 may still contain lead paint, while homes built after 1978 are unlikely to have lead-based paint.[16] The U.S. Department of Housing and Urban Development's Office of Healthy Homes and Lead Hazard Control performs regular studies of housing-based health hazards in the U.S.

[edit] See also

[edit] References

- ^ [1]

- ^ "RRP Overview & Contractor Certification".

- ^ http://www.jsonline.com/news/wisconsin/91440959.html

- ^ http://testudoonline.com/content/window-and-door-dealers-voice-opposition-expanded-lead-law

- ^ http://testudoonline.com/node/20

- ^ http://www.epa.gov/lead/pubs/renovaterightbrochure.pdf

- ^ www.epa.gov/lead/pubs/sbcomplianceguide.pdf

- ^ http://www.courts.ri.gov/supreme/pdf-files/Corrected%20Version%20State%20v.%20Lead%20Paint%20Industries%20Assoc.,%20Inc..pdf

- ^ Thomas R. Bender: "State of Rhode Island v. Lead Industries Association"

- ^ http://www.courts.mo.gov/courts/pubopinions.nsf/0f87ea4ac0ad4c0186256405005d3b8e/2886f48a874d6f28862572f8006c6ff8?OpenDocument

- ^ http://lawlibrary.rutgers.edu/courts/supreme/a-73-05.doc.html

- ^ http://www.legalnewsline.com/news/214352-paint-industrys-appeal-of-contingent-fee-contract-will-be-heard-by-calif.-sc

- ^ Court Decisions on Contingency Fee in Public Nuisance Litigations Item 2

- ^ John O'Brien: Another paint suit brushed away

- ^ "Center for Disease Control and Prevention". Retrieved June 24, 2010.

- ^ http://www.cpsc.gov/cpscpub/pubs/5054.html What You Should Know About Lead Based Paint in Your Home: Safety Alert, Consumer Product Safety Commission, Accessed 08-30-2010

[edit] External links

- US National Lead Information Center

- Healthy Homes and Lead Hazard Control

- Medical Knowledge of the Dangers of Lead-Based Paint

Here is more information from Wikipedia about house painting and decorating:

House painter and decorator

From Wikipedia, the free encyclopedia

| The examples and perspective in this article may not represent a worldwide view of the subject. Please improve this article and discuss the issue on the talk page. (December 2010) |

Contents[hide] |

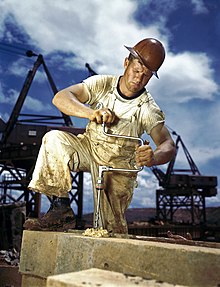

[edit] History of the trade

In England, little is known of the trade and its structures before the late 13th century, at which point guilds began to form, amongst them the Painters Company and the Stainers Company. These two guilds eventually merged with the consent of the Lord Mayor of the City of London in 1502, forming the Worshipful Company of Painter-Stainers. The guild standardised the craft and acted as a protector of the trade secrets. In 1599, the guild asked Parliament for protection, which was eventually granted in a bill of 1606, which granted the trade protection from outside competition such as plasterers.[2]The Act legislated for a sevens year apprenticeship, and also barred plasterers from painting, unless apprenticed to a painter, with the penalty for such painting being a fine of £5. The Act also enshrined a maximum daily fee of 16 old pence for their labour.[2]

Enforcement of this Act by the Painter-Stainers Company was sought up until the early 19th century, with master painters gathering irregularly to decide the fees that a journeyman could charge, and also instigating an early version of a job centre in 1769, advertising in the London newspapers a "house of call" system to advertise for journeymen and also for journeymen to advertise for work. The guild's power in setting the fee a journeyman could charge was eventually overturned by law in 1827, and the period after this saw the guild's power diminish, along with that of the other guilds; the guilds were superseded by trade unions, with the Operative United Painters' Union forming sometime around 1831.[2]

In 1894, a national association formed, recreating itself in 1918 as the National Federation of Master Painters and Decorators of England and Wales, then changing its name once again to the British Decorators Association before merging, in 2002, with the Painting & Decorating Federation to form the Painting & Decorating Association. The Construction Industry Joint Council, a body formed of both unions and business organizations, today has responsibility for the setting of pay levels.[2]

[edit] Tools of the trade

The modern composition of paints results in latex formulations being widely used for exterior as well as interior. That reduces post painting cleanup, and reduces the smells associated with petroleum and polyester based paints. Computerized paint scanners formulate new paints to match the often faded colour of existing paints. Many chain stores offer colour matching service.Modern paints are available in various specialized formulations that can be fade resistant, chip resistant, odor free, antibiotic to resist mould and fungi growth, etc.

For surfaces where a very smooth surface is desired, most retailers carry inexpensive chemicals that can be added to paints to better make the paint flow or lay flat.[3] Such additives are preferable to thinning paint, which can change some of the paint's characteristics.

For the layman, the most confusing element is primer and priming surfaces. For surfaces such as wood, paint alone is too thick and will be on the surface, but not adhere well, resulting in flaking. Primer is a thin paint solution, or even a specialized liquid colour coordinated to support the finish coat, which penetrates into the pores of wood, and allows the finish coat to adhere to the underlying primer.

Priming also results in less paint being needed. For unpainted wood, most laymen expect to apply two coats of paint. However, one coat of inexpensive primer and then a finish coat is much less expensive.

For metal surfaces, primer may involve special characteristics to resist corrosion, prevent impact chipping or improve adhesion of the finish coat.

Especially for problem paint jobs, such as new work, fungal presence or peeling paint, most professional paint retailers offer free consulting services. When their instructions and materials are used, guarantees of 5 to 20 years are available as to adhesion, water proofing, etc. of the finished paint job.

For professional painters, the majority of their time is spent in preparation for paint application, not in painting per se. Cleaning and sanding surfaces, taping and applying paper or plastic to surfaces not to be painted typically involve 50% or more of the painter's total time budget.

Although the brush and the fabric roller were the tools most readily associated with the painter, foam brushes are now commonly used for precise work requiring a straight line. Foam brushes can also be used to create a smoother surface using less paint that dries more quickly than brush applications.[4] Like fabric rollers, foam rollers can also create patterns in the painted surface. Foam rollers are available in a variety of professional materials for high-quality applications. [5] Although used in a variety of applications, the foam roller is commonly used during the painting of doors to produce an extremely smooth finish.

Recent advances in manufacture have led to a standardization of brushes, with many older types of brushes falling from fashion.[2] The spray gun is one of the latest tools in the painter's arsenal. It is powered by an electric, pneumatic or fuel powered motor which pumps paint through a hose into a gun which atomizes the paint to a fine spray. With the airless spray gun it is possible to paint extremely large areas of surface in a short time.

However, sprayed paint when dry can display unsightly patterns if the spraying application does not result in an even distribution of paint.

The ground brush, also known as a pound brush, was a round or elliptical brush bound by wire, cord or metal. They were generally heavy to use, and required considerable usage to break them in. These brushes were predominantly used in the days before modern paint manufacturing techniques; hand-mixed paints requiring more working to create the finish. These brushes still have use in applying primer, as they are useful in working the primer into the grain of the wood. Pound brushes required an even breaking in to create even bevel on both sides of the brush, minimising the formation of a point which would render the brush useless.[2] Sash tools were smaller brushes, similar to a ground brush, and used mainly for cutting in sash or glazing bars found on windows.

Sash tools and ground brushes generally required bridling before use, and a painter's efficiency in this skill was generally used as a guide to their overall ability. Both these brushes have largely been superseded by the modern varnish brush. Varnish brushes are the most common flat brushes available today and are used for painting as well as varnishing. Brushes intended for varnishing typically have a bevelled edge.[2]

Distemper brushes, used for applying distemper, an early form of whitewash, were best made of pure bristle and bound by copper bands to prevent rust damage. Styles differed across the world, with flat nailed brushes popular in Northern England, a two knot brush (a brush with two ovular heads) popular in Southern England, and three knot brushes or flat head brushes preferred elsewhere. In the United States distemper brushes were known as calcimine, kalsomine or calsomine brushes, each term being the U.S. variant of whitewash.[2]

Fitches are smaller brushes, either ovular or flat and one inch wide, that are used in fine work such as to pick out the detail on a painted moulding. Stipplers come in various shapes and sizes and are used to apply paint with a stippled effect. A duster or jamb brush was used to dust the area to be painted before work commenced. Stencil brushes, similar in style to a shaving brush, were used for the purpose of stencilling walls or in the creation of hand-made wallpapers.[2]

Brushes are best stored in a purpose made brush keeper, a box on which a wire could be suspended. The wire would be threaded through the hole in a brush's handle so as to suspend the brush in a cleaning solution without allowing the brush to sit on the bottom of the container and thus cause spreading of the bristles. The solution would also prevent hardening of the brushes and oxidization. These were generally rectangular and stored several brushes. A lid would enclose the brushes and keep them free from dust.[2]

If brushes are cleaned after use, they can last for years. Since most modern exterior and interior paints are latex based, cleaning the brushes after use with hot soapy water and a toothbrush can remove all traces of paint. Oil based paints are normally cleaned with a petroleum solvent such as mineral spirits, again using a toothbrush to remove all traces of paint. Metal "combs" are used to penetrate into the bristles of a brush to remove drying paint.

Although paints are now available in no-drip containers to pour paint into trays for roller application, most paints are sold in metal gallon or quart cans. For large jobs, paints come in 5-gallon containers.

For metal cans, a large diameter nail or punch is used to make drain holes in the lip of the can. The holes allow paint to return into the can. The lid can then be reattached correctly and removed later. Without the drain holes paint will accumulate in the lip, and act as an adhesive preventing the lid from being easily removed later. Closing a lid with paint in the lip can also result in paint travelling 15-feet or more horizontally.

The air in partly filled paint cans forms over time a dried surface film. To prevent development of film, prior to closing a latex paint container add a small amount of distilled (or tap) water that will remain on the top and prevent drying. For oil based paints use the solvent recommended for brush cleaning. When the container is reopened, stir the water/solvent into the paint before using.

Drop cloths, brown painter's paper, dust-sheets, paint sheets, paint tarpaulins or plastic protection films are used to protect nearby surfaces that are not being painted.

Masking tape can be used to define the line between the painted and unpainted surface, as well as to hold protection materials in place. Masking tape is available in several categories. The classic tape is a high adhesive. However it can damage the underlying surface when removed, and the longer it's in place the greater the risk of damage.

Modern delay removal tape prevents damaging the taped surface.[6] "Delicate" tape has about 40% the adhesion of traditional tape, and can remain on a surface for up to 30-days without creating damage.[7]

The less adhesive tapes should be used especially when tape is applied to new work. Depending on the paint composition, "dry" paint may still be soft and easily damaged for 30-days or more.

Some modern house painters in the US, Canada and Australia have adopted colour visualization computer software, developed by companies such as Autech Software & Design, as an additional tool to help demonstrate to customers how their home would look after it is painted. House painters can use a digital photo outputted by this software to show possible colour schemes on the client's home exterior or room walls to help with their colour selection.

[edit] Activities of the trade

Historically, the painter was responsible for the mixing of the paint; keeping a ready supply of pigments, oils, thinners and driers. The painter would use his experience to determine a suitable mixture depending on the nature of the job. In modern times, the painter is primarily responsible for preparation of the surface to be painted, such as patching holes in drywall, using masking tape and other protection on surfaces not to be painted, applying the paint and then cleaning up.[2]Larger firms operating within the trade were generally capable of performing many painting or decoration services, from sign writing, to the gilding of objects or the finishing or refinishing of furniture.[2]

More recently, professional painters are responsible for all preparation prior to painting. All scraping, sanding, wallpaper removal, caulking, drywall or wood repair, patching, stain removal, filling nail holes or any defects with plaster or putty, cleaning, taping, preparation and priming are considered to be done by the professional contracted painter.

Before repainting, surfaces are usually cleaned with sugar soap (in Commonwealth countries) which usually contains sodium carbonate, sodium phosphate, and sometimes sodium silicate as an abrasive, though formulations vary. In the U.S.A. a similar compound known as TSP is used but some modern formulations do not contain phosphates due to environmental concerns.

Professional painters need to have keen knowledge of tools of the trade, including sanders, scrapers, paint sprayers, brushes, paint rollers, ladders and scaffolding, in addition to just the paint in order to correctly complete work. Much preparation needs to be considered before simply applying paint. For instance, taping and dropcloth techniques, sizes of brushes or rollers, material types or dimensions of rollers or brushes (there are different sizes or types of brushes and rollers for different paints), amount of paint, number of paint coats, amount of primer, types of primers and paints, certain grits and cuts of sandpaper, trim cutting (the act of painting with a brush on the outline of baseboard, mouldings and other trim work), wallpaper removal, and nail-hole filling techniques. Today many painters are attempting to break into the field of faux painting, allowing them more creativity and access to a higher end customer base.

[edit] See also

[edit] References

| Wikimedia Commons has media related to: Painters (trade) |

- ^ Alf Fulcher (2005). Painting and Decorating. Blackwell Publishing. ISBN 1405112549.

- ^ a b c d e f g h i j k l m The Modern Painter and Decorator volume 1 1921 Caxton

- ^ http://www.floodco.com/paint-additive-solutions/index.jsp

- ^ http://news.thomasnet.com/fullstory/486648

- ^ http://www.woosterbrush.com/Catalog/RollerCovers/Minirollers

- ^ http://www.maxitape.com/tape/products/tapes/industry/industrial-masking-and-packaging/pt-14-blue-painter-s-tape.html

- ^ http://www.findtape.com/shop/product.aspx?id=276&setscreen=1&width=1024&height=610

Industrial painting

From Wikipedia, the free encyclopedia

| The introduction to this article provides insufficient context for those unfamiliar with the subject. Please help improve the article with a good introductory style. (April 2010) |

- "The machine may very well be the appropriate instrument for the creation of an industrial-inflationist art, based on the Anti-Patent; the new industrial culture will be strictly "Made Amongst People" or not at all! The time of the Scribes is over."

- "When thousands of painters who today labor at the non-sense of detail will have the possibilities which machines offer, there will be no more giant stamps, called paintings to satisfy the investment of value, but thousands of kilometers of fabric offered in the streets, in markets, for barter, allowing millions of people to enjoy them and exciting the experience of arrangement."

[edit] See also

[edit] References

[edit] External links

| This painting-related article is a stub. You can help Wikipedia by expanding it. |

Epoxy

From Wikipedia, the free encyclopedia

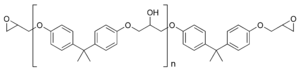

Epoxy or polyepoxide is a thermosetting polymer formed from reaction of an epoxide "resin" with polyamine "hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic materials and general purpose adhesives.Contents[hide] |

[edit] Chemistry

Structure of TETA, a typical hardener. The amine (NH) groups react with the epoxide groups of the resin during polymerization.

The process of polymerization is called "curing", and can be controlled through temperature, choice of resin and hardener compounds, and the ratio of said compounds; the process can take minutes to hours. Some formulations benefit from heating during the cure period, whereas others simply require time, and ambient temperatures.

[edit] History

The first commercial attempts to prepare resins from epichlorohydrin were made in 1927 in the United States. Credit for the first synthesis of bisphenol-A-based epoxy resins is shared by Dr. Pierre Castan of Switzerland and Dr. S.O. Greenlee of the United States in 1936. Dr. Castan's work was licensed by Ciba, Ltd. of Switzerland, which went on to become one of the three major epoxy resin producers worldwide. Ciba's epoxy business was spun off and later sold in the late 1990s and is now the advanced materials business unit of Huntsman Corporation of the United States. Dr. Greenlee's work was for the firm of Devoe-Reynolds of the United States. Devoe-Reynolds, which was active in the early days of the epoxy resin industry, was sold to Shell Chemical (now Hexion, formerly Resolution Polymers and others).[edit] Applications

The applications for epoxy-based materials are extensive and include coatings, adhesives and composite materials such as those using carbon fiber and fiberglass reinforcements (although polyester, vinyl ester, and other thermosetting resins are also used for glass-reinforced plastic). The chemistry of epoxies and the range of commercially available variations allows cure polymers to be produced with a very broad range of properties. In general, epoxies are known for their excellent adhesion, chemical and heat resistance, good-to-excellent mechanical properties and very good electrical insulating properties. Many properties of epoxies can be modified (for example silver-filled epoxies with good electrical conductivity are available, although epoxies are typically electrically insulating). Variations offering high thermal insulation, or thermal conductivity combined with high electrical resistance for electronics applications, are available.[3][edit] Paints and coatings

Two part epoxy coatings were developed for heavy duty service on metal substrates and use less energy than heat-cured powder coatings. These systems use a 4:1 by volume mixing ratio, and dry quickly providing a tough, protective coating with excellent hardness. Their low volatility and water clean up makes them useful for factory cast iron, cast steel, cast aluminum applications and reduces exposure and flammability issues associated with solvent-borne coatings. They are usually used in industrial and automotive applications since they are more heat resistant than latex-based and alkyd-based paints. Epoxy paints tend to deteriorate, known as chalk out, due to UV exposure.Polyester epoxies are used as powder coatings for washers, driers and other "white goods". Fusion Bonded Epoxy Powder Coatings (FBE) are extensively used for corrosion protection of steel pipes and fittings used in the oil and gas industry, potable water transmission pipelines (steel), concrete reinforcing rebar, et cetera. Epoxy coatings are also widely used as primers to improve the adhesion of automotive and marine paints especially on metal surfaces where corrosion (rusting) resistance is important. Metal cans and containers are often coated with epoxy to prevent rusting, especially for foods like tomatoes that are acidic. Epoxy resins are also used for high performance and decorative flooring applications especially terrazzo flooring, chip flooring[4] and colored aggregate flooring.[5]

[edit] Adhesives

Some epoxies are cured by exposure to ultraviolet light. Such epoxies are commonly used in optics, fiber optics, optoelectronics, and dentistry.[citation needed]

[edit] Industrial tooling and composites

Epoxy systems are used in industrial tooling applications to produce molds, master models, laminates, castings, fixtures, and other industrial production aids. This "plastic tooling" replaces metal, wood and other traditional materials, and generally improves the efficiency and either lowers the overall cost or shortens the lead-time for many industrial processes. Epoxies are also used in producing fiber-reinforced or composite parts. They are more expensive than polyester resins and vinyl ester resins, but usually produce stronger and more temperature-resistant composite parts.[edit] Electrical systems and electronics

Flexible epoxy resins are used for potting transformers and inductors. By using vacuum impregnation on uncured epoxy, winding-to-winding, winding-to-core, and winding-to-insulator air voids are eliminated. The cured epoxy is an electrical insulator and a much better conductor of heat than air. Transformer and inductor hot spots are greatly reduced, giving the component a stable and longer life than unpotted product.

Epoxy resins are applied using the technology of resin dispensing.

[edit] Consumer and marine applications

Epoxies are sold in hardware stores, typically as a pack containing separate resin and hardener, which must be mixed immediately before use. They are also sold in boat shops as repair resins for marine applications. Epoxies typically are not used in the outer layer of a boat because they deteriorate by exposure to UV light. They are often used during boat repair and assembly, and then over-coated with conventional or two-part polyurethane paint or marine-varnishes that provide UV protection.There are two main areas of marine use. Because of the better mechanical properties relative to the more common polyester resins, epoxies are used for commercial manufacture of components where a high strength/weight ratio is required. The second area is that their strength, gap filling properties and excellent adhesion to many materials including timber have created a boom in amateur building projects including aircraft and boats.

Normal gelcoat formulated for use with polyester resins and vinylester resins does not adhere to epoxy surfaces, though epoxy adheres very well if applied to polyester resin surfaces. "Flocoat" that is normally used to coat the interior of polyester fibreglass yachts is also compatible with epoxies.

Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden quickly, particularly if a lot of catalyst is used. The chemical reactions in both cases are exothermic. Large quantities of mix will generate their own heat and greatly speed the reaction, so it is usual to mix small amounts which can be used quickly.

While it is common to associate polyester resins and epoxy resins, their properties are sufficiently different that they are properly treated as distinct materials. Polyester resins are typically low strength unless used with a reinforcing material like glass fibre, are relatively brittle unless reinforced, and have low adhesion. Epoxies, by contrast, are inherently strong, somewhat flexible and have excellent adhesion. However, polyester resins are much cheaper.

Epoxy resins typically require a precise mix of two components which form a third chemical. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in every case they must be mixed exactly. The final product is then a precise thermo-setting plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature.

By contrast, polyester resins are usually made available in a 'promoted' form, such that the progress of previously-mixed resins from liquid to solid is already underway, albeit very slowly. The only variable available to the user is to change the rate of this process using a catalyst, often Methyl-Ethyl-Ketone-Peroxide (MEKP), which is very toxic. The presence of the catalyst in the final product actually detracts from the desirable properties, so that small amounts of catalyst are preferable, so long as the hardening proceeds at an acceptable pace. The rate of cure of polyesters can therefore be controlled both by the amount of catalyst and by the temperature.

As adhesives, epoxies bond in three ways: a) Mechanically, because the bonding surfaces are roughened; b) By proximity, because the cured resins are physically so close to the bonding surfaces that they are hard to separate; c) Ionically, because the epoxy resins form ionic bonds at an atomic level with the bonding surfaces. This last is substantially the strongest of the three. By contrast, polyester resins can only bond using the first two of these, which greatly reduces their utility as adhesives and in marine repair.

[edit] Aerospace applications

In the aerospace industry, epoxy is used as a structural matrix material which is then reinforced by fiber. Typical fiber reinforcements include glass, carbon, Kevlar, and boron. Epoxies are also used as a structural glue. Materials like wood, and others that are 'low-tech' are glued with epoxy resin.[edit] Art

Epoxy resin, mixed with pigment, is used as a painting medium, by pouring layers on top of each other to form a complete picture.[7][edit] Wind Energy applications

Epoxy resin is used in manufacturing the rotor blades of wind turbines. The resin is infused in the core materials, such as balsa wood or foam, and the reinforcing media, such as fabric, glass fibre or carbon fibre. The process is called VARTM, i.e. Vacuum Assisted Resin Transfer Moulding. Due to excellent properties and good finish, epoxy is the most favoured resin for composites.[edit] Industry

As of 2006, the epoxy industry amounts to more than US$5 billion in North America and about US$15 billion worldwide. The Chinese market has been growing rapidly, and accounts for more than 30% of the total worldwide market. It is made up of approximately 50–100 manufacturers of basic or commodity epoxy resins and hardeners of which the three largest are Hexion (formerly Resolution Performance Products, formerly Shell Development Company; whose epoxy tradename is "Epon"), the Dow Chemical Company (tradename "D.E.R."), and Huntsman Corporation's Advanced Materials business unit (formerly Vantico, formerly Ciba Specialty Chemical; tradename "Araldite"). In 2007 Huntsman Corporation agreed to merge with Hexion (owned by the Apollo Group).[8][9] KUKDO Chemical is one of the largest epoxy manufacturers in Asia, and recently their capacity has been increased up to 210,000 MT/Y (Korea 150,000 MT/Y, China 60,000 MT/Y and will be increased totally 300,000 MT/Y by 2009). Nanya Plastic also has the capacity of over 250,000 MT/Y (Taiwan and China), which is mostly for captive use. There are over 50 smaller epoxy manufacturers primarily producing epoxies only regionally, epoxy hardeners only, specialty epoxies, or epoxy modifiers.These commodity epoxy manufacturers mentioned above typically do not sell epoxy resins in a form usable to smaller end users, so there is another group of companies that purchase epoxy raw materials from the major producers and then compounds (blends, modifies, or otherwise customizes) epoxy systems from these raw materials. These companies are known as "formulators". The majority of the epoxy systems sold are produced by these formulators and they comprise over 60% of the dollar value of the epoxy market. There are hundreds of ways that these formulators can modify epoxies—by adding mineral fillers (talc, silica, alumina, etc.), by adding flexibilizers, viscosity reducers, colorants, thickeners, accelerators, adhesion promoters, etc.. These modifications are made to reduce costs, to improve performance, and to improve processing convenience. As a result a typical formulator sells dozens or even thousands of formulations—each tailored to the requirements of a particular application or market.

[edit] Health risks

The primary risk associated with epoxy use is sensitization to the hardener, which, over time, can induce an allergic reaction. It is a main source of occupational asthma among users of plastics.[11] Bisphenol A, which is used in epoxy resin, is a known endocrine disruptor.[edit] See also

[edit] References

- ^ "Epoxy Chemistry". http://www.csuchico.edu/~jpgreene/m247/m247_ch02/sld023.htm.

- ^ "Epoxy Polymers". http://chem.chem.rochester.edu/~chem424/epoxy.htm.

- ^ May, Clayton A. (1987-12-23). Epoxy Resins: Chemistry and Technology (Second ed.). New York: Marcel Dekker Inc. p. 794. ISBN 0824776909.

- ^ Norm Lambert. "Chips Flooring". Epoxy.com. http://www.epoxy.com/chip.htm. Retrieved 2010-07-24.

- ^ Norman L. Lambert. "Quartz Flooring". Epoxy.com. http://www.epoxy.com/15.htm. Retrieved 2010-07-24.

- ^ Morena, John J (1988). Advanced Composite Mold Making. New York: Van Nostrand Reinhold Co. Inc. pp. 124–125. ISBN 9780442264147.

- ^ McCreight, Tim; Bsullak, Nicole. Color on Metal: 50 Artists Share Insights and Techniques. Madison, WI: Guild. p. 74. ISBN 1893164063.

- ^ Steve Gelsi, "Huntsman OK's $10.6 bln takeover offer from Apollo's Hexion", Market Watch, July 12, 2007.

- ^ Market Participant, "Hexion IPO Creates Way Too Much Debt", June 22, 2006.

- ^ "Market Report: World Epoxy Resin Market". Acmite Market Intelligence. http://www.acmite.com/market-reports/chemicals/world-epoxy-resin-market.html.

- ^ MayoClinic --> Occupational asthma May 23, 2009

[edit] External links

- Epoxy Resin health hazards (California Department of Health Services)

- The chemistry of epoxide, simple to understand

Drywall

From Wikipedia, the free encyclopedia

For the musical group, see Drywall (musical project).

| This article needs additional citations for verification. Please help improve this article by adding reliable references. Unsourced material may be challenged and removed. (July 2009) |

Example of drywall with joint compound, the common interior building material. (This photo shows drywall hung vertically.)

Plasterboard panels are also known as wallboard (USA, UK, Ireland),[citation needed] Gibraltar board or GIB wall and ceiling linings (in New Zealand, trademark of Winstone Wallboards[1]), rock lath,[2] Sheetrock (a trademark of USG Corporation), Gyproc (in Australia, a trademark of Compagnie de Saint-Gobain).

The sheets of the drywall can be made from fiberglass instead of paper to prevent mold growth. Mold growth is common when using paper-based plasterboard that has been exposed to water due to plumbing leaks or floods.

Drywall construction became prevalent as a speedier alternative to using plaster-based interior finish techniques, which involved forcefully spreading a substrate of coarse plaster, known as the base (made up of the scratch coat and (optional) brown coat), onto the wall's lath-work before finally applying the smoother finish coat, each layer added in succession and all by hand (see lath and plaster).[3] Drywall, by contrast to plaster, requires hand finishing only at the fasteners and joints. The drywall process requires less labor and drying time, lending its name to the panels used in the assembly.[citation needed]

Contents[hide] |

[edit] History

"Sackett Board" was invented in 1894 by Augustine Sackett. It was made by layering plaster within four plies of wool felt paper. Sheets were 36" x 36" x 1/4" thick with open (untaped) edges."[4]"Gypsum Board" evolved between 1910 and 1930 beginning with wrapped board edges, and elimination of the two inner layers of felt paper in favor of paper-based facings. Providing efficiency of installation, it was developed additionally as a measure of fire resistance. [5] Later air entrainment technology made boards lighter and less brittle, then joint treatment materials and systems also evolved. "[4]

"Rock Lath" was an early substrate for plaster. An alternative to traditional wood or metal lath, it was a panel made up of compressed gypsum plaster board that was sometimes grooved or punched with holes to allow wet plaster to key into its surface. As it evolved, it was faced with paper impregnated with gypsum crystals that bonded with the applied facing layer of plaster.[2]

[edit] Specifications

[edit] USA and Canada

Drywall panels are manufactured in 48 inches (120 cm) wide panels in varying lengths to suit the application. Common panel thicknesses are 1/2" (13 mm) and 5/8" (16 mm), with panels also available in 1/4" (6 mm) and 3/8" (10 mm). Both 1/2" (13 mm) and 5/8" (16 mm) panels of TYPE 'X' (a gypsum board with special core additives to increase the natural fire resistance of regular gypsum board[7]) are used where a fire-resistance rating is desired. Regular 5/8" (16 mm) panels are used (with or without light gauge resilient metal channels) where additional mass is needed for the reduction of sound transmission.[citation needed]Drywall provides a thermal resistance R-value (in US units) of 0.32 for 3/8" board, 0.45 for 1/2", 0.56 for 5/8", and 0.83 for 1" board. In addition to increased R-value, thicker drywall has a higher sound transmission class.[citation needed]

[edit] Europe

In the UK and Europe, plasterboard is manufactured in metric sizes, with the common sizes being corollaries of old imperial sizes.Most plasterboard is made in 120 cm wide sheets, though 90 cm and 60 cm wide sheets are also made. 120 cm wide plasterboard is most commonly made in 240 cm lengths, though 270 cm and 300 cm length sheets are also commonly available.

Commonly used thicknesses of plasterboard available are 12.5 mm (modern equivalent of half an inch), typically used for walls, and 9.5 mm (modern equivalent of three-eights of an inch), typically used for ceilings. 15 mm thick board is commonly available, and other thicknesses are also produced.[citation needed]

Plasterboard is commonly made with one of two different edge treatments—tapered edge, where the long edges of the board are tapered with a wide bevel at the front to allow for jointing materials to be finished flush with the main board face, and plain edge, used where the whole surface will receive a thin coating (skim coat) of finishing plaster.

[edit] Construction techniques

Drywall is cut to size, using a large T-square, by scoring the paper on the front side (usually white) with a utility knife, breaking the sheet along the cut, scoring the paper backing, and finally breaking the sheet in the opposite direction. Small features such as holes for outlets and light switches are usually cut using a keyhole saw or a small high-speed bit in a rotary tool. Drywall is then fixed to the wall structure with nails, glue, or more commonly in recent years, the now-ubiquitous drywall screws.

Drywall fasteners, also referred to as drywall clips or stops, are gaining popularity in both residential and commercial construction. Drywall fasteners are used for supporting interior drywall corners and replacing the non-structural wood or metal blocking that traditionally was used to install drywall. Their function serves to save on material and labour expenses; to minimize call backs due to truss uplift; to increase energy efficiency; and to make plumbing and electrical installation simpler.

Drywall screws heads have a curved taper, allowing them to self-pilot and install rapidly without punching through the paper cover. These screws are set slightly into the drywall. When drywall is hung on wood framing, screws having an acute point and widely spaced threads are used. When drywall is hung on light-gauge steel framing, screws having an acute point and finely spaced threads are used. If the steel framing is heavier than 20-gauge, self-tapping screws with finely spaced threads must be used. In some applications, the drywall may be attached to the wall with adhesives.

After the sheets are secured to the wall studs or ceiling joists, the seams between drywall sheets are concealed using joint tape and several layers of joint compound (sometimes called mud). This compound is also applied to any screw holes or defects. The compound is allowed to air dry then typically sanded smooth before painting. Alternatively, for a better finish, the entire wall may be given a skim coat, a thin layer (about 1 mm or 1/16 inch) of finishing compound, to minimize the visual differences between the paper and mudded areas after painting.

Another similar skim coating is always done in a process called veneer plastering, although it is done slightly thicker (about 2 mm or 1/8 inch). Veneering uses a slightly different specialized setting compound ("finish plaster") that contains gypsum and lime putty. This application uses blueboard, which has special treated paper to accelerate the setting of the gypsum plaster component. This setting has far less shrinkage than the air-dry compounds normally used in drywall, so it only requires one coat. Blueboard also has square edges rather than the tapered-edge drywall boards. The tapered drywall boards are used to countersink the tape in taped jointing whereas the tape in veneer plastering is buried beneath a level surface. One coat veneer plaster over dry board is an intermediate style step between full multi-coat "wet" plaster and the limited joint-treatment-only given "dry" wall.

[edit] Water damage and mold

Drywall is easily damaged by exposure to water. While it can be waterproofed through covalent waterproofing, if waterproofing is absent or if the waterproofing layer is punctured, water will cause drywall to swell and eventually disintegrate, requiring replacement. Drywall is a porous, lightweight substance that supports the growth of mold. It is for this reason that greenboard and cement board is used for rooms expected to have high humidity.[edit] Fire resistance

When used as a component in fire barriers, drywall is a passive fire protection item. In its natural state, gypsum contains the water of crystallization bound in the form of hydrates. When exposed to heat or fire, this water is vapourised, retarding heat transfer. Therefore, a fire in one room that is separated from an adjacent room by a fire-resistance rated drywall assembly will not cause this adjacent room to get any warmer than the boiling point (100°C) until the water in the gypsum is gone. This makes drywall an ablative material because as the hydrates sublime, a crumbly dust is left behind, which, along with the paper, is sacrificial. Generally, the more layers of Type X drywall one adds, the more one increases the fire-resistance of the assembly, be it horizontal or vertical. Evidence of this can be found both in publicly available design catalogues, including, but not limited to DIN4102 Part 4 and the Canadian Building Code on the topic, as well as common certification listings, including but not limited to certification listings provided by Underwriters Laboratories and Underwriters Laboratories of Canada (ULC). "Type X" drywall is formulated by adding glass fibers to the gypsum, to increase the resistance to fires, especially once the hydrates are spent, which leaves the gypsum in powder form. Type X is typically the material chosen to construct walls and ceilings that are required to have a fire-resistance rating.

Finished, painted, fire-resistance rated drywall assembly. A common deficiency: Lift ceiling tiles and find electrical and mechanical service penetrations without a firestop.

|

Improper firestop and fireproofing interface, August 2000

| ||

The "I-was-there-first" scenario, resulting in improper drywall firestops with plastic piping.

|

When tests are cosponsored, resulting in code recognized designs with assigned fire-resistance ratings, the resulting designs become part of the code and are not limited to use by any one manufacturer, provided the material used in the field configuration can be demonstrated to meet the minimum requirements of Type X drywall (such as an entry in the appropriate category of the UL Building Materials Directory) and that sufficient layers and thicknesses are used. Fire test reports for such unique third party tests are confidential.

Deflection of drywall assemblies is important to consider to maintain the integrity of drywall assemblies in order to preserve their ratings. The deflection of drywall assemblies can vary somewhat from one test to another. Importantly, penetrants do not follow the deflection movement of the drywall assemblies they penetrate. For example, see cable tray movement in a German test. It is, therefore, important to test firestops in full scale wall panel tests, so that the deflection of each applicable assembly can be taken into account. The size of the test wall assembly alone is not the only consideration for firestop tests. If the penetrants are mounted to and hung off the drywall assembly itself during the test, this does not constitute a realistic deflection exposure insofar as the firestop is concerned. In reality, on a construction site, penetrants are hung off the ceiling above. Penetrants may increase in length, push and pull as a result of operational temperature changes (e.g., hot and cold water in a pipe), particularly in a fire, but it is a physical impossibility to have the penetrants follow the movement of drywall assemblies that they penetrate, since they are not mounted to the drywalls in a building. It is, therefore, counterproductive to suspend penetrants from the drywall assembly during a fire test. As downward deflection of the drywall assembly and buckling towards the fire occurs, the top of the firestop is squeezed and the bottom of the firestop is pulled, and this is motion over and above that, which is caused by the expansion of metallic penetrants, due to heat exposure in a fire. Both types of motion occur in reality, because metal first expands in a fire and then softens once the critical temperature has been reached, as is explained under structural steel. To simulate the drywall deflection effect, one can simply mount the penetrants to the steel frame holding the test assembly. The operational and fire induced motion of the penetrants, which is independent of the assemblies penetrated, can be separately arranged.

[edit] Waste

Because up to 17% of drywall is wasted during the manufacturing and installation processes[citation needed] and the drywall material is frequently not re-used, disposal can become a problem. Some landfill sites have banned the dumping of drywall. Some manufacturers take back waste wallboard from construction sites and recycle it into new wallboard. Recycled paper is typically used during manufacturing. More recently, recycling at the construction site itself is being investigated. There is potential for using crushed drywall to amend certain soils at building sites, such as sodic clay and silt mixtures (bay mud), as well as using it in compost.[13][edit] Types available in the USA and Canada

- Regular white board, from 1/4" to 3/4" thickness

- Fire-resistant ("Type X"), different thickness and multiple layers of wallboard provide increased fire rating based on the time a specific wall assembly can withstand a standardized fire test. Often perlite, vermiculite and boric acid are added to improve fire resistance.

- Greenboard, the drywall that contains an oil-based additive in the green colored paper covering that provides moisture resistance. It is commonly used in washrooms and other areas expected to experience elevated levels of humidity.[citation needed]

- Blueboard, blue face paper forms a strong bond with a skim coat or a built-up plaster finish providing both water and mold resistance.

- Cement board, which is more water-resistant than greenboard, for use in showers or sauna rooms, and as a base for ceramic tile

- Soundboard is made from wood fibers to increase the sound rating (STC)

- Soundproof drywall is a laminated drywall made with gypsum, other materials, and damping polymers to significantly increase the STC[citation needed]

- Mold-resistant, paperless drywall[citation needed]

- Enviroboard, a board made from recycled agricultural materials

- Lead-lined drywall, a drywall used around radiological equipment[citation needed]

- Foil-backed drywall to control moisture in a building or room[citation needed]

- Controlled density (CD), also called ceiling board, which is available only in 1/2" thickness and is significantly stiffer than regular white board.

- EcoRock, a drywall which uses a combination of 20 materials including recycled fly ash, slag, kiln dust and fillers and no starch cellulose; it is advertised as being environmentally-friendly due to the use of recycled materials and an energy efficient process.[14]

- Gypsum “Firecode C.” This board is similar in composition to Type X,except that it has more glass fibers,and, it has another ingredient in the gypsum core. This ingredient is a shrinkage-compensating additive, a form of vermiculite. When exposed to high heat, the gypsum core shrinks but the shrinkage-compensating element expands at about the same rate as shrinkage occurs in the water-depleted gypsum.

[edit] Common drywall tools

- Benches

- Chalk line

- Corner trowel

- Dimpler

- Drywall adhesive glue guns

- Drywall cart

- Drywall fastener

- Drywall (hatchet) hammer

- Drywall lifter

- Drywall jack

- Drywall screws and nails

- Electric screwdriver

- Keyhole saw or drywall router

- Pencil

- Surform

- Screw gun

- Stud finder

- Tape measure

- Taping knife

- T-square

- Utility knife

[edit] Levels of finish

"In 1990, four major trade associations, the Association of Wall and Ceiling Industries International (AWCI), the Ceilings and Interior Systems Construction Association (CISCA), the Gypsum Association (GA), and the Painting and Decorating Contractors of America (PDCA), presented the consensus document Levels of Gypsum Board Finish. The document was created to "precisely describe" the desired finish of walls and ceilings prior to final decoration. This precise description enables contractors to better understand the requirements of architects and building owners in order to enhance the satisfaction of the client. Specifications that include the Levels of Gypsum Board Finish also promote competitive bidding that allows the bidder to consider the correct labor and materials to finish the wall suitably for its final decoration." [15]The official document (summarized below) is known as GA-214-96 "Recommended Levels of Gypsum Board Finish".

[edit] Level 0